Emial Us :

sales2@hjauto.com.cn

The hot wire ignition tester is a precision testing equipment designed by the source manufacturer specifically for material fire safety. It comprehensively evaluates the fire hazard of materials by simulating the high-temperature ignition scenario of electric heating wires.

Brand :

HONGCEModel :

HWI-1Certificate :

Calibration certificate(cost additional)Product Origin :

ChinaPayment Method :

L/C, T/TRegular Packaging :

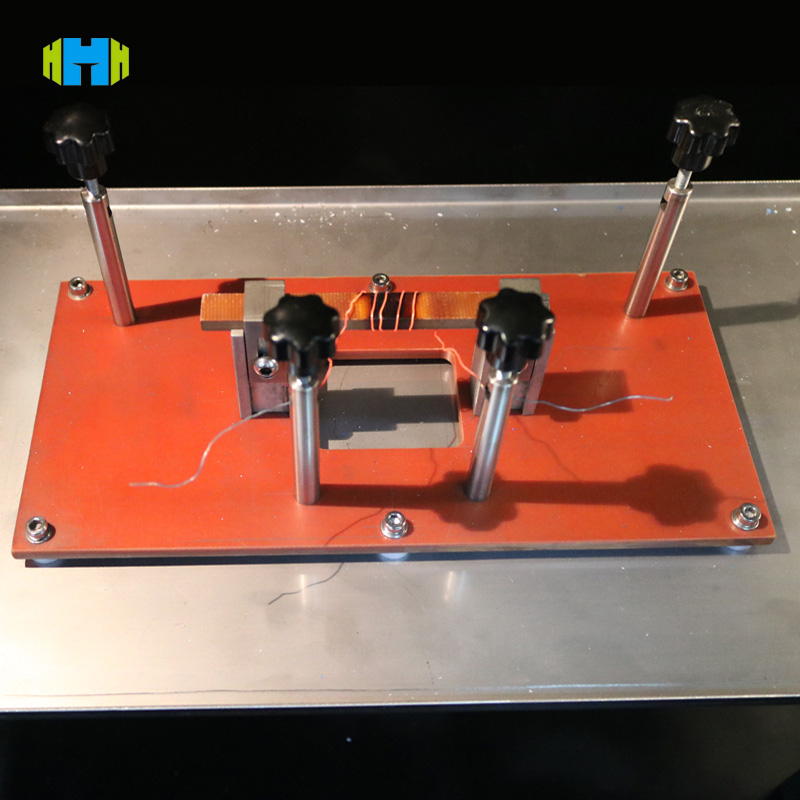

PlywoodHWI-1 Hot Wire Ignition Tester IEC60695-2-20 certified 0.26W/mm precise temperature control 120 seconds ignition test

Product Introduction:

The HWI-1 Hot Wire Ignition Tester is independently developed and produced by HongCe Company and is designed for testing the ignition characteristics of materials under extreme high temperatures. The equipment uses high-precision electric heating wire (Ni80/Cr20 alloy) to wind the sample and heat it to glow, simulating the thermal stress environment in a real fire, and accurately recording the ignition time and material reaction.

Product Use:

Applicable to synthetic materials, insulating parts, plastic products, etc., widely used in fire protection certification of electronic equipment, automotive parts, and building materials, helping companies avoid fire risks during product design and meet global market access requirements.

Reference standards:

| Standard number | Test clause | Applicable fields |

| IEC60695-2-20:2006 | Ignition test method for heating wire | Fire protection certification for electronic equipment |

| UL746A:2006 | Evaluation of combustion performance of polymer materials | Plastic product safety test |

| GB4943.1-2001 | Safety requirements for information technology equipment | China Compulsory Certification (CCC) |

| ASTM D3874:1997 | Determination of ignition time of materials at high temperature | Industrial materials research and development |

| IEC60950-1:2005 | Fire protection specification for information technology equipment | Global market access |

Technical parameters:

| Projects | Parameters |

| Working voltage | 220V/50Hz |

| Control operation mode | Electrical control, button operation |

| Heating coil | ф0.5mm,Ni80/Cr20,length:250mm±5mm ,cold resistance 5.28Ω/m |

| Anneal holder distance | 250mm |

| Specimen holder distance and height | 70mm,height:60mm (the distance between the holder surface to the tray surface) |

| Wire wrapping tension and its distance | 5.4N±0.05N, 6.35mm±0. 5mm (within 31.5mm±0.5mm,coil 5 cycle,national standard is 6mm) |

| Annealing time and power | 8s~12s(1s~999.9s digital display can be preset),0.26W/mm±4%(digital display is adjustable) |

| Testing time and power | 120s(1s~999.9s digital display can be preset),0.26W/mm±4%( digital display is adjustable) |

| Specimen size | L×W×H:(125 ± 5mm) ×(13.0 ± 0.5mm) ×(0.75+0.075 0mm,1.5+0.15 0mm,3+0.3 0mm)[national standard is 0.75± 0.1 mm,1.5± 0.1 mm,3± 0.2 mm] |

| Test procedure | Automatic control, independent exhaust |

| Lighting | Equip with lighting in the test chamber, with control |

| Test chamber and dimension | >0.5m3,black matte background,with exhaust fan,dimension:1100*550*1200mm,130kg |

Test objects and test items:

Applicable materials:

Synthetic resin (ABS, PC, PP)

Insulating rubber, silicone seals

Flame retardant coating, fire retardant paint

Test items:

Material ignition time (TIR)

Deformation and carbonization degree under thermal stress

Flame retardant grade (UL94 V-0/V-1/V-2)

Smoke release (gas analysis module optional)

Detail pictures:

Our hours

Mon 11/21 - Wed 11/23: 9 AM - 8 PM

Thu 11/24: closed - Happy Thanksgiving!

Fri 11/25: 8 AM - 10 PM

Sat 11/26 - Sun 11/27: 10 AM - 9 PM

(all hours are Eastern Time)