Emial Us :

sales2@hjauto.com.cn

UL1581 HVW-1 Wire and Cable Flame Test Chamber is an intelligent testing device designed for evaluating the flame retardant performance of wires and cables. By precisely controlling the flame height, burning time and gas flow, it simulates a real fire scene, helping you quickly determine the fire resistance level of the material and ensure product quality and safety.

Brand :

HONGCEModel :

HVW-1Certificate :

Calibration certificate(cost additional)Product Origin :

ChinaPayment Method :

L/C, T/TRegular Packaging :

PlywoodUL1581 Wire and Cable Flame Test Chamber Vertical/Horizontal Flame Test Complies with ASTM, IEC standards

Product introduction:

The UL1581 wire and cable combustion test chamber is independently developed and produced by HongCe. The equipment uses a full stainless steel box and a tempered glass observation window, combined with a PLC intelligent control system and a touch screen operation interface, supports wireless remote control and automatic data recording, and greatly improves test efficiency and accuracy. Whether it is vertical combustion (VW-1, FT1) or horizontal combustion (FT2, electrical wire test), it can perfectly meet the requirements of international standards such as UL, IEC, and ASTM, providing global customers with reliable fire performance verification solutions.

International standards:

UL1581: 1080 sections (VW-1 vertical burning), 1100 sections (horizontal specimen/FT2), 1090 sections (horizontal burning of electrical wires), 1060 sections (vertical burning/FT1).

ASTM D5025: Specification for manufacturing and flame calibration of blowtorches.

IEC 60332-1-2: Vertical burning test method for single wires and cables.

GB/T 18380.1-2001: Applicable to cable burning test with conductor diameter ≥ 0.8mm.

Technical parameters:

| Project | Parameters |

| Working voltage | 220V/50Hz |

| Control operation mode | PLC control, 7 inch color touch screen operation, with infrared remote control |

| Burner standard | ASTM D 5025,diameter:9.5mm ± 0.5mm,length:100mm,made of brass |

| Gas flow |

Vertical test: 965±30ml/min or 117±3 mm;horizontal test: 440±10mL/min or 58±1mm, Flow meter adjustment |

| Gas pressure | 0.1MPa |

| U type pressure gauge back pressure water column height | Vertical test: 125±10 mm;horizontal test: 45±5mm |

| Combustion time / residual glow time | 9999X0.1S |

| Combustion angle | 0°,20°,45°,Adjustable |

| Test flame calibration | Temperature measuring copper head:Ф9mm±0.01mm,weight before drilling:10 ± 0 .05g |

| Thermocouple:The American original Omega φ0.5 armour nickel-chromium/nickel aluminum wire K-Thermocouple,temperature resistance 1100° | |

| Distance between the bunsen burner port to temperature measuring copper block:Vertical test:55±1 mm;horizontal test:25mm | |

|

Flame height: Vertical test: Inner flame:40±2mm,Outer falme:125mm; horizontal test: Inner flame:16.5±1.5mm,Outer flame:50±4mm |

|

| Temperature rise time from 100±5°C to 700°±3°C:Vertical test:54±2S; horizontal test:84±2s | |

| Gas category | Purity>98% methane |

Product use:

Test objects:

1. Rubber insulated cable

2. Thermoplastic cable

3. Soft wire installation line

4. Household lead-in cable

Test items:

Evaluation of flame spread capability

Analysis of burning characteristics of insulating materials

Determination of burning time and self-extinguishing performance

Verification of flame height and temperature distribution

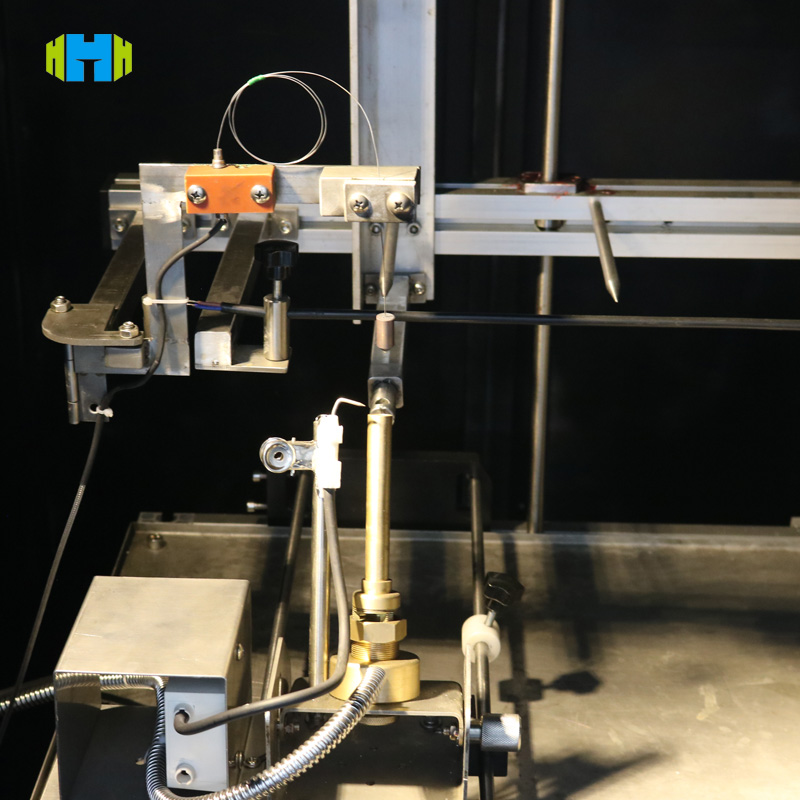

Detail pictures:

Our hours

Mon 11/21 - Wed 11/23: 9 AM - 8 PM

Thu 11/24: closed - Happy Thanksgiving!

Fri 11/25: 8 AM - 10 PM

Sat 11/26 - Sun 11/27: 10 AM - 9 PM

(all hours are Eastern Time)