Emial Us :

sales2@hjauto.com.cn

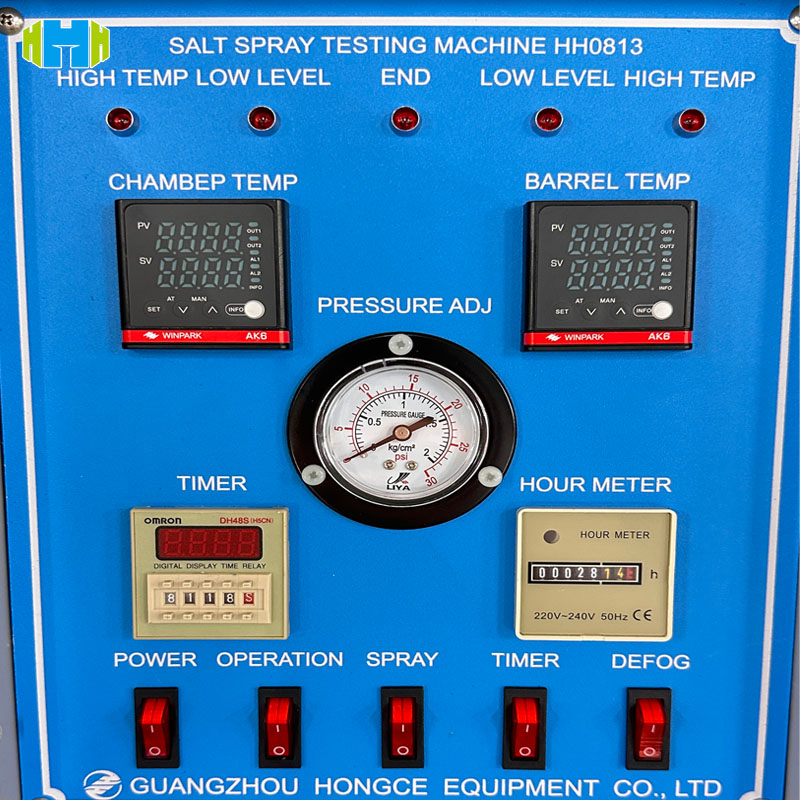

HH0813 salt spray test chamber is specially designed for testing the corrosion resistance of materials! As a source manufacturer, HongCe uses ingenuity to create high-precision environmental testing equipment, supporting multi-standard cyclic corrosion testing, covering industries such as industry, electronics, and automobiles. Intelligent temperature control, anti-crystallization nozzles, and humanized design allow your products to withstand harsh environmental challenges and protect every quality commitment!

Brand :

HH0813Model :

1 setCertificate :

NegotiatableProduct Origin :

ChinaPayment Method :

5 sets per monthHH0813 Salt Spray Test Chamber Cyclic Corrosion Test ASTM B117 Standard Environmental Test Equipment

Product Introduction:

In today's fierce global competition, the corrosion resistance of products is the key to winning market trust. The HH0813 salt spray test chamber manufactured by HongCe Company takes "precision, reliability, and efficiency" as its core, simulates complex environments such as salt spray, humidity, heat, and dryness, and comprehensively evaluates the corrosion resistance of coatings, electroplating, metals, and electronic components. Whether it is salt spray aging testing of automotive parts or anti-rust verification of high-end electronic products, it can provide accurate data to help you discover potential defects in advance and ensure the durability of products in harsh environments.

International Reference Standards:

ASTM B117-2023: Standard salt spray test specification, applicable to coatings, electroplated parts, etc.

ISO 9227:2022: Salt spray test method for artificial environment corrosion testing.

GB/T 10125-2021: Chinese national standard, equivalent to international salt spray test requirements.

DIN 50021: German industrial standard, cyclic corrosion test process.

JIS Z 2371:2015: Japanese industrial standard, salt spray tolerance evaluation of electronic products.

Product use:

Industrial field: Corrosion resistance verification of automotive parts, aviation materials, and ship coatings.

Electronic industry: Rust resistance test of PCB circuit boards, connectors, and shells.

Consumer product testing: Salt spray aging evaluation of home appliance surface treatment, hardware tools, and outdoor equipment.

Scientific research institutions: New material development, anti-corrosion process optimization, and environmental adaptability research.

Technical Parameters:

| Model | HH0813 | HH0813A | HH0813B | HH0813C | HH0813D | ||||

| Inner chamber size (mm) | 600*450*400 | 900*600*500 | 1200*800*600 | 1600*800*600 | 2000*800*600 | ||||

| Outer chamber size (mm) | 1070*600*1180 | 1410*880*1280 | 1900*1180*1600 | 2300*1180*1500 | 2700*1180*1600 | ||||

| Test chamber temperature | Salt water test method (NSS ACSS)35℃±1℃/ corrosion resistance test method(CASS)50℃±1℃ | ||||||||

| Pressure barrel temperature | Salt water test method(NSS ACSS)47℃±1℃/ corrosion resistance test method(CASS)63℃±1℃ | ||||||||

| Salt water temperature | 35℃±1℃ 50℃±1℃ | ||||||||

| Test chamber capacity | 108L | 270L | 480L | 800L | 1440L | ||||

| Salt water tank capacity | 15L | 25L | 40L | 40L | 40L | ||||

| Salt concentration | Sodium Chloride Solution concentration of 5% or add 0.26g of copper chloride (CuCl2 2H2O) per every liter of the Sodium Chloride Solution in the concentration of 5% | ||||||||

| Compressed air pressure | 1.00±0.01kgf/cm² | ||||||||

| Spray amount | 1.0~2.0ml/80cm²/h (collecting at least for 16 hours, take the average) | ||||||||

| Relative humidity of testing chamber | More than 85% | ||||||||

| Acid value PH | 6.5~7.2 3.0~3.2 | ||||||||

| Spray mode | Programmable spray (including continuous spray and intermittent spray) | ||||||||

| Meet the standards | JIS, ASTM, CNS | ||||||||

| Power supply | 120V,60Hz | ||||||||

Test objects and inspection items:

Test objects: metal plating, organic coating, automotive parts, electronic components, plastic parts, etc.

Inspection items: salt spray corrosion rate, coating adhesion, electrochemical corrosion, rust level, material durability evaluation.

Detail pictures:

Our hours

Mon 11/21 - Wed 11/23: 9 AM - 8 PM

Thu 11/24: closed - Happy Thanksgiving!

Fri 11/25: 8 AM - 10 PM

Sat 11/26 - Sun 11/27: 10 AM - 9 PM

(all hours are Eastern Time)