Emial Us :

sales2@hjauto.com.cn

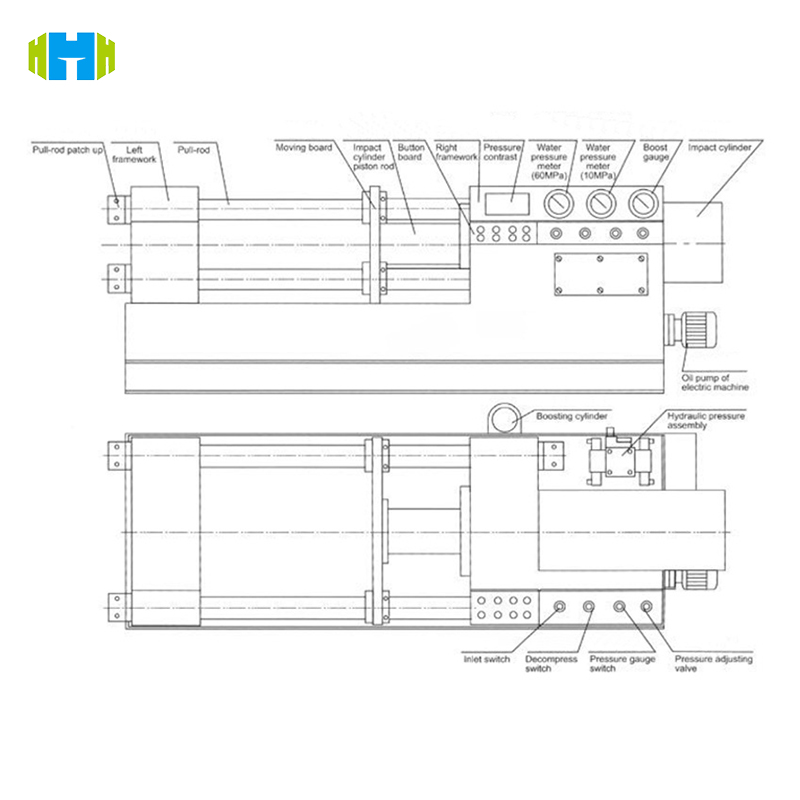

WPT-3 is specially designed for high-pressure valve testing. It adopts a 500kN hydraulic pressure system (accuracy ±1%), supports 4 independent testing stations for DN50-DN800 valves, and covers 0-150MPa water pressure/air pressure testing. Equipped with a PLC intelligent control system and a 10-inch touch screen, it automatically completes shell strength (1.5PN) and seal leakage (1.1PN) tests, and complies with ASME B16.34 and API 598 international standards. It is the core testing equipment for petrochemical, nuclear power, and high-pressure pipeline projects.

Brand :

CHINAModel :

HONGCECertificate :

Calibration certificate(cost additional)Product Origin :

WPT-3Payment Method :

NegotiatableRegular Packaging :

PlywoodTop Pressure Valve Test Bench 500kn Top Pressure 4 Independent Test Stations Asme B16.34

Product Introduction

WPT-3 achieves efficient and accurate detection of high-pressure valves through top-pressure structure and multi-station design:

Product Features

High-pressure full compatibility

Multi-dimensional detection capability

Intelligent data management

Quick clamping design

International reference standards

Product use

Technical Parameters

| Category | Parameter Details |

| Model | WPT-3 |

| Top Pressure Range | 20-500kN (Resolution: 0.1kN) |

| Test Pressure Range | 0-150MPa (Hydraulic), 0-100MPa (Pneumatic) |

| Workstations | 4 Independent Stations (Optional 8 Stations) |

| Test Port Size | DN50-DN800 (Flange/Butt-Welded/Threaded Connections) |

| Drive System | Hydraulic Servo + Plunger Pump (Power: 18.5kW, Response Time: <15ms) |

| Control Interface | 10-inch LCD Touch Screen (1280×800 Resolution) |

| Pressure Accuracy | ±0.3%FS (Hydraulic), ±0.5%FS (Pneumatic) |

| Leakage Detection | 0.05mL/min (Hydraulic), 0.1ppm (Pneumatic) |

| Data Storage | 64GB Built-in Memory (Supports 100,000+ Test Records) |

| Temperature Range | -10-60℃ (Working), -20-70℃ (Storage) |

| Power Supply | AC380V±10%, 50Hz, Rated Power: 30kW |

| Protection Class | IP55 (Control Cabinet), IP67 (Test Chamber) |

| Dimensions | 3000×2500×2800mm (L×W×H, Including Hydraulic Station) |

| Weight | 1800kg (Net Weight, Stainless Steel Structure) |

| Communication | RS485/Modbus TCP, USB 3.0, Ethernet |

| Load Types | Water, Air, Nitrogen (Optional Oil Medium) |

Test objects and inspection items

Test objects:

High-pressure flange valves (gate valves, stop valves, ball valves, PN ≥ 100)

Butt-welded valves (such as high-temperature and high-pressure valves for power stations)

Threaded safety valves (such as compressor bypass valves)

Special working condition valves (corrosion-resistant, impact-resistant, and low-temperature valves)

Inspection items:

Shell strength test: 1.5 times the nominal pressure for 30 minutes, no deformation, no leakage.

Seal test:

Upper seal: 1.1 times the nominal pressure, leakage ≤ 0.1mL/min (DN50).

Sealing surface: Bubble method detection, no continuous bubbles are generated (equivalent leakage ≤ 0.05mL/min).

Air sealing test: 0.6MPa air pressure, pressure maintenance for 60 minutes, pressure decay ≤ 0.2%.

Top pressure matching test: Calculation of minimum sealing force under different test pressures (optimization of clamping efficiency).

Fatigue test: 1000 cycles of pressurization, sealing surface wear ≤ 0.05mm.

Our hours

Mon 11/21 - Wed 11/23: 9 AM - 8 PM

Thu 11/24: closed - Happy Thanksgiving!

Fri 11/25: 8 AM - 10 PM

Sat 11/26 - Sun 11/27: 10 AM - 9 PM

(all hours are Eastern Time)