Emial Us :

sales2@hjauto.com.cn

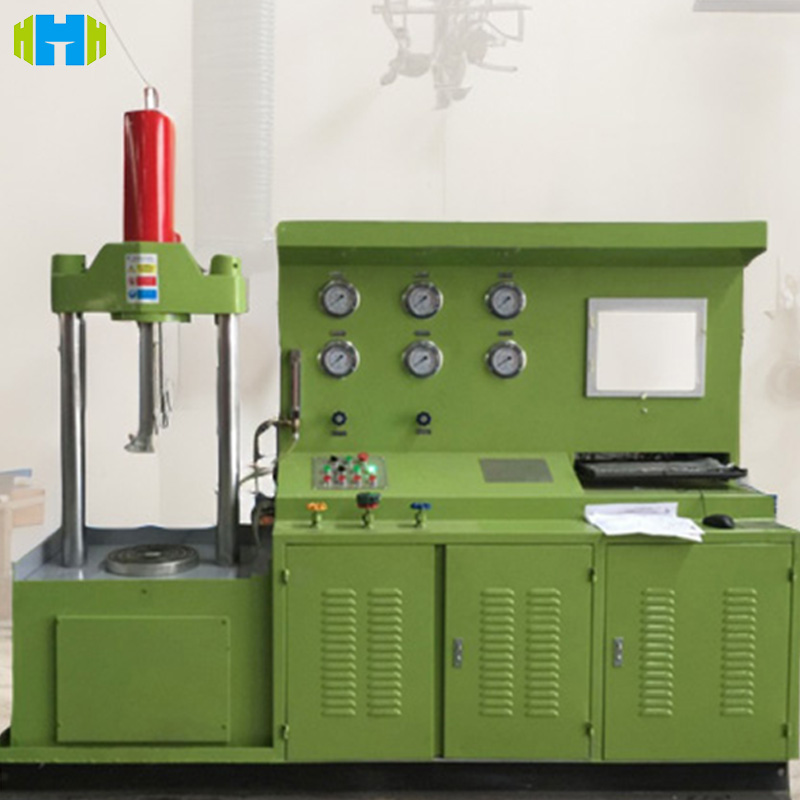

WPT-7 is an intelligent testing device designed for vertical valves and flow meters. It supports 0.1-200m³/h flow test (accuracy ±0.3%) and 0-40MPa pressure test, integrating 15+ core index tests such as flow characteristics, sealing, and pressure resistance. It adopts a vertical modular structure, can quickly replace DN25-DN300 equipment in 10 minutes, is equipped with a 10-inch touch screen and PLC intelligent control system, and automatically generates test reports that comply with ISO 5167 and API 6D standards. It is suitable for equipment research and development, production quality inspection and certification testing in the water, petrochemical, and energy industries.

Brand :

HONGCEModel :

WPT-14Certificate :

Calibration certificate(cost additional)Product Origin :

CHINAPayment Method :

L/C, T/TRegular Packaging :

PlywoodVertical Valve Flow Meter Intelligent Test Bench High-Precision Flow Detection Full-Caliber Adaptation Iso5167

Product Introduction

WPT-7 redefines the performance verification standard of valves/flowmeters with vertical efficient detection and intelligent measurement and control technology:

1. Vertical structure and efficient detection

2. Multi-dimensional performance testing

Flow detection:

Range 0.1-200m³/h (electromagnetic flowmeter calibration accuracy ±0.3%), supports clean water, oil, and natural gas media (optional anti-corrosion module to cope with acid and alkali environments)

Flow characteristic test: linearity, repeatability error (≤0.1%), pressure loss analysis (resolution 0.01MPa)

Pressure test:

0-40MPa Static pressure test (accuracy ±0.2% FS), meeting 1.5 times nominal pressure shell strength test and 1.1 times sealing test (leakage ≤ 0.01L/min liquid)

Pulse pressure test (frequency 0-10Hz) simulates pipe network water hammer impact and detects equipment fatigue life

3. Intelligent measurement and control and data management

Operation interface: 10-inch color touch screen (1280×800), one-button switch between Chinese and English, built-in ISO 5167, API 6D and other 20+ standard test templates, parameter setting time shortened by 40%

Data traceability: 64G encrypted storage + USB/Ethernet export, automatic generation of flow-pressure curve, leakage trend chart, upper computer software supports PDF report generation (including compliance determination)

4. Safety and reliability design

Hardware protection: stainless steel high-pressure chamber (pressure resistance 60MPa) + tempered explosion-proof observation window (light transmittance 92%), leakage monitoring accuracy up to 0.001L/min

Triple protection: automatic overpressure unloading (110% set value), motor overheating shutdown (>70℃), emergency power-off button (response time <0.5s), in line with EN 61010-1 electrical safety standards

Product features

🚀 Quick clamping Electric lifting + pneumatic locking, DN300 equipment replacement time <10 minutes, compatible with multi-brand valves/flow meters

🔬 High-precision detection German imported sensors: flow ±0.3% FS, pressure ±0.2% FS, calibrated by CNAS, meet ISO 5167 Class 1 accuracy

🌐 Standard compatibility Built-in API 6D, EN 12266-1 test procedures, automatically generate data reports required for CE/API/CCC certification

📊 Intelligent analysis Real-time SPC statistics (CPK value/process capability index), abnormal data AI Identification (accuracy 98%) and sound and light alarm

⚙️ Flexible expansion Optional high temperature module (0-150℃), vacuum system (vacuum degree ≤10kPa), adapt to extreme working conditions test requirements

International reference standards

Flow measurement standards:

Valve test standards:

Safety and electromagnetic compatibility:

| Category | Parameter Details |

| Model | WPT-7 |

| Flow Test Range | 0.1-200m³/h (Accuracy: ±0.3%FS, Electromagnetic Flowmeter) |

| Pressure Test Range | 0-40MPa (Static Pressure), 0-25MPa (Pulse Pressure) |

| Test Media | Water, Hydraulic Oil, Natural Gas (Optional Anti-Corrosion Coating for Acid/Alkali) |

| Temperature Range | Operating: 0-80℃; Storage: -20-70℃ |

| Leakage Detection | Liquid: ≤0.01L/min; Gas: ≤0.1m³/h |

| Control System | PLC + 10-inch Touch Screen (1280×800 Resolution, Multi-Language Support) |

| Data Storage | 64GB Built-in SSD (Supports 100,000+ Test Records, USB/Ethernet Export) |

| Test Port Size | DN25-DN300 (Flange/Threaded/Butt-Welded Connections) |

| Drive System | Servo Motor (Power: 15kW, Speed: 0-3000rpm) |

| Protection Class | IP54 (Control Cabinet), IP65 (Test Chamber) |

| Power Supply | AC380V±10%, 50/60Hz, Rated Power: 25kW (Peak: 35kW) |

| Dimensions | 2500×1800×3000mm (L×W×H, Including Support Frame) |

| Weight | 2000kg (Stainless Steel Frame + Aluminum Alloy Fixtures) |

| Communication | RS485/Modbus TCP, USB 3.0, Ethernet (Support OPC UA Protocol for MES Integration) |

| Noise Level | ≤75dB (Measured at 1m Distance, No-Load Operation) |

| Service Category | Details |

| Warranty | 2-year warranty for the whole machine, 5-year warranty for sensors and servo systems, lifetime cost-price maintenance for core components (PLC/touch screen) |

| Response Mechanism | 24-hour English-Chinese technical support (phone/remote assistance), customized solutions within 48 hours, 7-day delivery for domestic orders |

| Value-Added Services | Free on-site installation and debugging (including training for 3 personnel, ISO/API standard test procedure demonstration), lifetime free software upgrades, hardware module expansion (e.g., high-temperature/high-pressure test components) |

| Quality Traceability | Provided with equipment calibration reports (issued by CNAS-certified laboratories), supporting 3-year historical data query and traceability |

Our hours

Mon 11/21 - Wed 11/23: 9 AM - 8 PM

Thu 11/24: closed - Happy Thanksgiving!

Fri 11/25: 8 AM - 10 PM

Sat 11/26 - Sun 11/27: 10 AM - 9 PM

(all hours are Eastern Time)